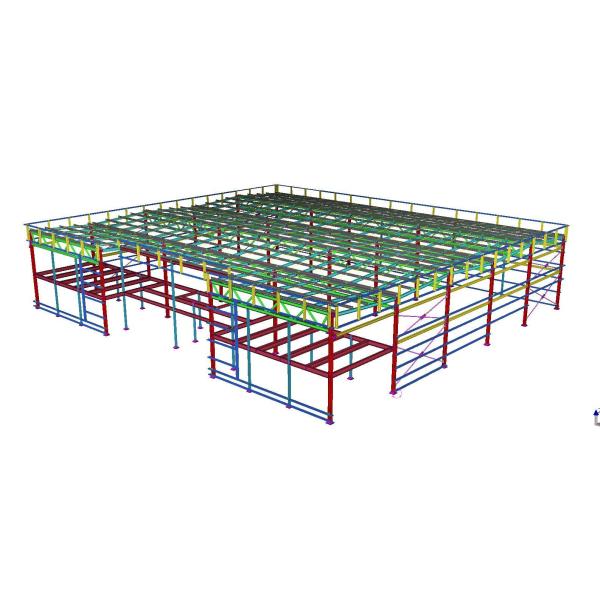

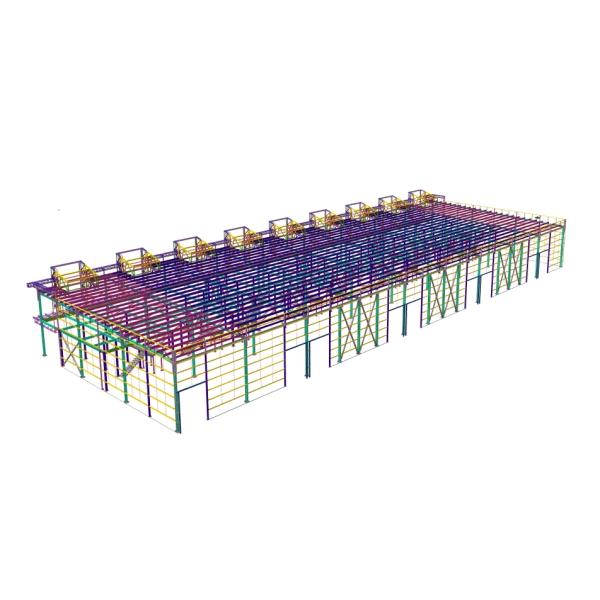

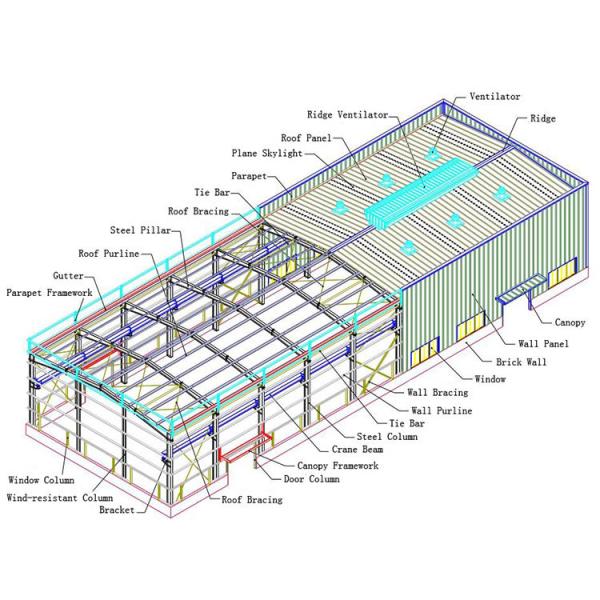

Steel Building Metal Prefabricated Building Steel Space Frame Construction Building Warehouse

Product Specifications

| Attribute | Value |

| Type | Portal Frame Structure |

| Design software | PKPM, Tekla structures, CAD |

| Material | Q235B/Q355B Steel |

| Main frame | Welded H-shape Steel Beam |

| Welding method | SAW, MIG, GMAW |

| Surface treatment | Anti-corrosive paint or hot dipped galvanized |

| Life Time | Main Structure 35-50 Years |

| Delivery Time | 25-40 Days |

| Standard | GB Standard |

| Material Grade | Q355B, Q235B |

| Structure type | Portal frame |

| Design Load | Wind, Snow, Seismic |

Product Description

Steel Wooden Hybrid Commercial Building Flat Pack Container Steel Warehouse

At TSIN, all steel structure components are meticulously fabricated to meet your specific requirements. We manufacture strictly according to your detailed drawings and specifications.

You can also purchase structural steel produced to international standards, including EN, DIN, ASTM, and JIS, ensuring compliance with global quality benchmarks.

Additionally, we supply overseas sectional steel profiles such as IPE, IPN, UB, and W beams, available with a minimum order quantity of 60 tons.

Key Features

- Lightweight yet Strong: The high strength-to-weight ratio and large span capability significantly reduce foundation load.

- Faster Construction: Prefabrication allows for simpler and quicker on-site assembly, shortening build time compared to traditional concrete methods.

- Cost-Effective: Investment costs are typically 20-30% lower than those of conventional building techniques.

- Durable: Exceptional fire resistance and corrosion protection ensure long-lasting performance.

- Flexible: Structures can be easily disassembled, relocated, and recovered in an environmentally friendly manner.

Additional Specifications

| Products | Steel structure Fabrication |

| Material | Q235B, Q345B, S235JR, S355JR, SS400, A36, A572Gr50, A992 |

| Surface treatment | 1. Painting; 2. Galvanized |

| Certification | ISO9001, ISO14001, OHSAS18001, EN1090, ISO3834 |

| Standard | GB, ASTM, EN, ISO, AS/ANS |

| Specification | Per drawing |

| Place of Origin | Shandong, China |

| MOQ | 20 Tons |

| Application | Steel Warehouse, Steel Workshop, Multi-storey Building |

Welding Procedures

TSIN undertake all welding procedures in accordance with GB standard. Our dedicated Welding Inspectors are certified by the government authority.

We perform non-destructive testing (NDT) in accordance with contract documents and applicable welding codes. As part of this process, we ensure that all inspections, test plans and quality manuals are fully documented and maintained.

Tests we conduct include:

- Dimension check

- Visual examination

- Ultrasonic testing

Frequently Asked Questions

Q1: Can I visit your factory before ordering?

A: Yes, we welcome factory visits. We can arrange airport pickup from Qingdao Airport and assist with hotel bookings.

Q2: How do we cooperate on a project?

A: Our process includes: 1) Reviewing your project requirements, 2) Providing free design drawings for your approval, 3) 30% deposit after contract signing, 4) Final design confirmation, 5) Production and final payment before shipment, 6) Optional installation support.

Q3: What is the price range?

A: Prices vary based on material quality, size, and design complexity, typically ranging from $19 to $100+ per square meter.

Q4: Do you provide installation service?

A: We provide detailed construction drawings and manuals. For additional support, we can send workers and engineers to your site (with costs covered by the buyer).

Q5: What is the delivery time?

A: Typically 30 days after deposit receipt, with partial shipments available for large orders.

Q6: What anti-rust treatments are available?

A: Options include: normal anti-rust paint, epoxy zinc primer, hot-dip galvanization, hot-dip galvanization with PU finish, or stainless steel structures (301/304/316).

Q7: How is quality controlled?

A: Our products meet CE EN1090 and ISO9001:2008 standards. We provide quality inspection reports to verify materials and manufacturing processes.